The Difference Between Plastic Blown Film Machine and Cast Film Machine: A Complete Analysis of Film Production Equipment

2025-04-28Many people mistakenly believe that all plastic films are produced by blown film machines. However, different types of films require different production equipment. Ordinary blown film machines are commonly used to produce shopping bags, express bags, and agricultural mulch films, while stretch wrap for packaging requires cast film machines. This article will provide a detailed analysis of the differences between blown film and cast film machines to help you better understand film production processes.

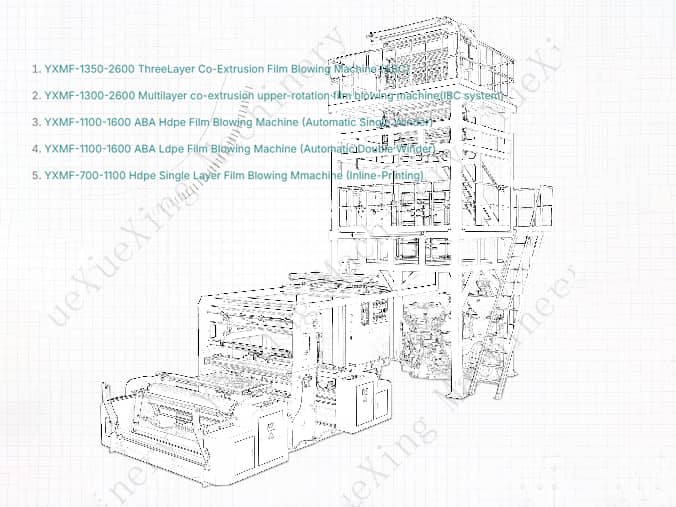

What is a Plastic Blown Film Machine?

A plastic blown film machine is a device that produces plastic films through the "blow molding" process. Its working principle involves extruding molten plastic material through a circular die to form a tubular film, which is then inflated by compressed air and cooled to form a thin film.

Applications of Blown Film Machines

Supermarket shopping bags

Express packaging bags

Agricultural mulch film

General packaging films

Features of Blown Film Machines

Lower production cost

Suitable for producing thicker films

Higher film strength

What is a Cast Film Machine?

The cast film machine uses the "casting" process to produce films. Its working principle involves extruding molten plastic material through a flat die, forming a film that is rapidly cooled and shaped. Films produced by this process have uniform thickness and high transparency, making them suitable for high-precision packaging needs.

Applications of Cast Film Machines

Stretch wrap / Pallet wrap

High-transparency packaging films

Medical films

Protective films for electronic products

Features of Cast Film Machines

More uniform film thickness

Higher clarity

Suitable for ultra-thin films

Conclusion

Blown film machines and cast film machines are two different types of plastic film production equipment, each with its own applications. Blown film machines are more suitable for general packaging films, while cast film machines excel in high-clarity and ultra-thin films. Choosing the right equipment can significantly improve production efficiency and product quality.

Previous:8 working principle diagrams of film blowing machine

Next:1350ABA High Pressure Film Blowing Machine Fully Recycled Materials