Application fields of ABA film blowing machine

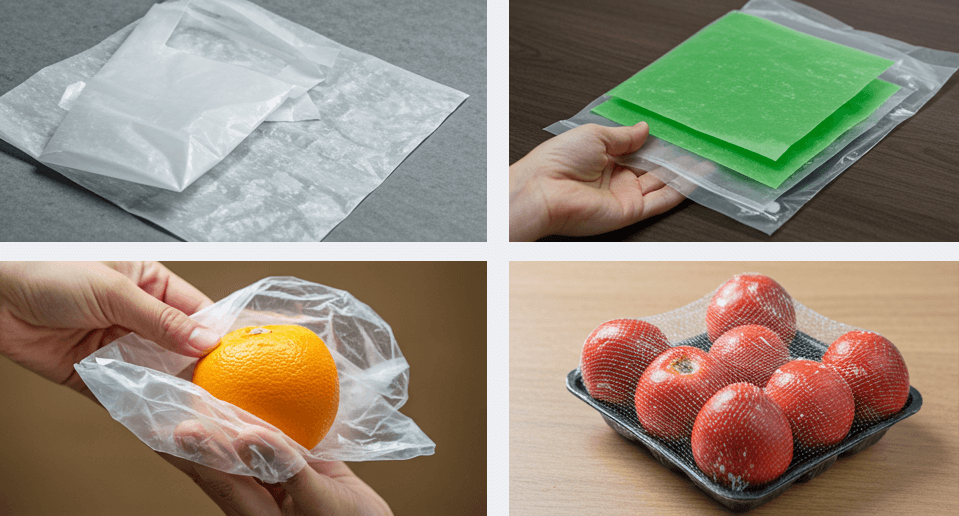

2025-04-07The products produced by ABA film blowing machine are widely used in many fields, such as T-shirt shopping bags, biodegradable plastic films and food, fruit packaging, supermarket shopping bags, express bags, etc.

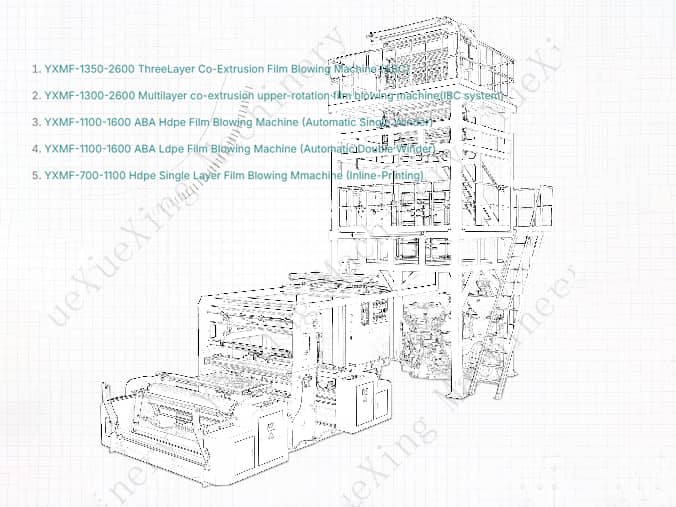

The machine has advantages in producing HDPE, LDPE and LLDPE materials. The strength of plastic film is improved by co-extrusion. In addition, although ABA film blowing machine has only two extrusion units, it can achieve three-layer film blowing. One unit handles the inner layer and the outer layer, while the other unit handles the inner layer. It can not only reduce costs and save energy. At the same time, in order to improve the market competitiveness of customers, 80% recycled materials and CACO3 can be added to the inner puffing layer.

Using recycled materials and CACO3 saves a lot more than using new materials. The film blowing machine uses the A layer as a coating for input, which can make the plastic film smooth and bright with good tensile resistance. The inner layer is filled with recycled materials and CAC03. Single-layer film blowing machine cannot achieve such a function. Compared with three-layer film blowing machine, it saves costs.

The co-extrusion ABA film blowing machine uses two screws to realize the function of a three-layer film blowing machine. The main body of the machine is scientifically designed, which saves costs and improves efficiency. Therefore, the application range is relatively wide, and reasonable and effective economic benefits can be achieved. Moreover, the ABA film blowing machine is simple and convenient to operate, and more cost-effective.

The ABA film blowing machine automatically loads, and the B-layer screw adopts an automatic fast screen changer to save time. In addition, the winding device adopts an automatic roll changing design, and the automatic roll changing is flexible and can be adjusted according to specifications such as length and weight. Only one experienced worker is required to handle all operations of the machine, making production easier and saving labor costs. Customers can quickly recover their investment by using cheaper raw materials and obtain very considerable profits.

The video of 2200 ABA High Pressure Film Blowing Machine

Previous:2200ABA High Pressure Film Blowing Machine - Express Bag Production Line