Real-World Applications of AI in Film-Blowing Machine

2025-10-09We have discussed this before:AI are Redefining Blown Film Production.

From a purely film-blowing machine production and R&D perspective, calling AI a "panacea" is undoubtedly an exaggeration. However, if it is defined as a powerful, progressively evolving tool, it's not an exaggeration; it's a reality that's happening now.

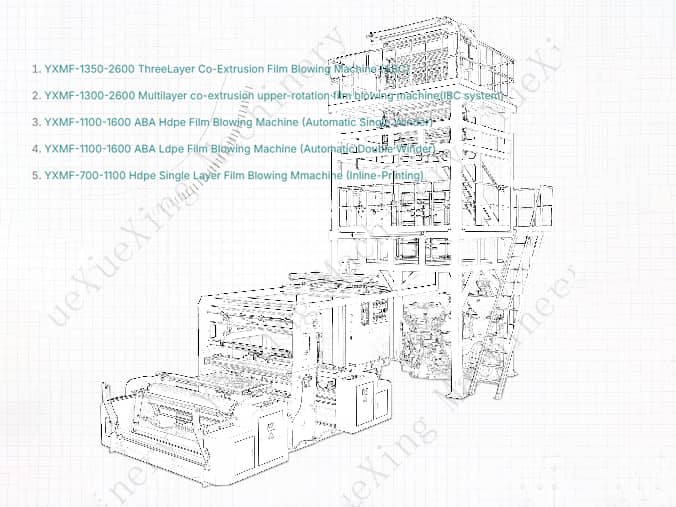

Real-World Applications of AI in Film-Blowing Machines

1. Predictive Maintenance: This is currently the most mature application with the clearest ROI.

Traditional Approach: Regular inspections or post-failure repairs. The former can lead to excessive maintenance, while the latter can cause unplanned downtime.

AI Approach: Vibration, temperature, and acoustic sensors are installed on key components (such as the main motor, gearbox, and screw bearings). AI models continuously analyze this data, learning the "healthy patterns" of normal operation. They can identify subtle abnormal patterns hours or even days in advance, accurately predicting failure risks.

Professional Value: Significantly reduces unplanned downtime, a core metric that production managers care about most. This is not an exaggeration; it represents a direct economic benefit.

2. Intelligent Quality Inspection (AI-based Machine Vision):

Traditional Method: Relies on manual visual inspection of the film surface, which is prone to fatigue, missed inspections, and high subjectivity.

AI Method: High-resolution cameras scan the film surface online. AI vision models, trained on a vast array of defect images (fisheyes, crystals, impurities, holes), can detect and classify defects with unprecedented speed, accuracy, and consistency.

Professional Value: Achieve 100% online inspection, establish an objective quality database, and provide precise feedback for process optimization. This has become standard for high-end film production.

3. Process Parameter Optimization Assistance (Frontier Exploration, but with Huge Potential):

This area is most susceptible to criticism of "exaggeration," but the logic is sound.

Challenges: Blown film process parameters (temperature, pressure, screw speed, and air volume) are interconnected, resulting in complex influences. The experience of experienced craftspeople is difficult to quantify and pass on.

AI Method: AI models do not directly "create" knowledge. Instead, they learn from vast amounts of historical production data (parameters, environment, raw material batches, and quality results) to identify complex nonlinear relationships that are difficult for humans to detect. For example, it can answer questions like, "Given the current ambient temperature and humidity, and this specific grade of LLDPE raw material, what is the optimal range of parameters to achieve the target thickness and gloss?"

Professional Value: Shortens startup and commissioning time, reduces scrap, and stabilizes quality. It doesn't replace process engineers; rather, it serves as a powerful decision support system, freeing them from tedious trial-and-error tasks and allowing them to focus on more complex innovations.