Towards 2026: How Customization, Modularity, Intelligence, and AI are Redefining Blown Film Production

2025-09-26Introduction

The market is pushing blown film technology beyond traditional paradigms. By 2026, successful film producers will rely on lines that excel in customization, modularity, intelligence, and begin exploring Artificial Intelligence (AI).

1. Customization: From "General-Purpose" to "Specialized"

The mark of professionalism is not how many film types a machine can produce, but how well it is optimized for one specific type.

Example: The requirements for screws, die geometry, and cooling systems for high-barrier packaging films versus biodegradable shopping bags are vastly different. True customization means targeted engineering from the ground up to ensure optimal processing of new/specialty materials (e.g., PLA, PBAT, high-performance PEs), maximizing yield and film properties.

2. Modularity: Flexibility to Navigate Uncertainty

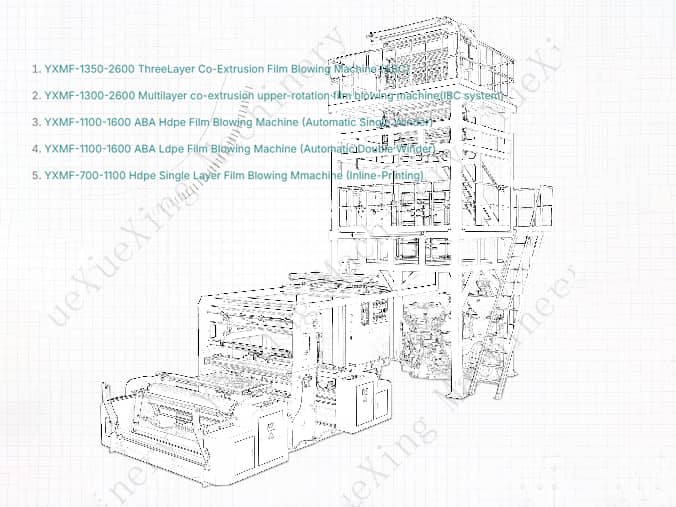

Modularity is the engineering foundation for cost-effective customization. It deconstructs the production line into independent functional units.

Professional Value:

Quick Changeovers: Ideal for small-batch, high-mix orders. Switching products becomes like swapping modular components, slashing downtime.

Technology Upgrades: Allows for future upgrades of specific modules, protecting initial investment.

Easier Maintenance: Standardized modules simplify spare parts and repairs.

3. Intelligence: From "Experience-Driven" to "Data-Driven"

Intelligence provides the machine with a "digital nervous system." Its professional application includes:

Closed-Loop Control: High-precision sensors monitor bubble stability and thickness in real-time, automatically adjusting air ring flow or screw speed for consistent quality, reducing reliance on operator experience.

Data Traceability: All production parameters are logged, providing a foundation for quality traceability and process replication.

4. AI: The Frontier of "Autonomous Optimization"

The AI mentioned here is more of a discussion about machine learning and program prediction, not the traditional understanding of AI. We will have the opportunity to discuss this in detail.

AI represents the next level of intelligence, currently in an exploratory phase. Key professional applications are:

Predictive Maintenance: Analyzes data like motor current and bearing vibration to predict component failure, shifting from reactive repair to proactive maintenance.

Intelligent Parameter Recommendation: Based on historical production data, AI models can suggest optimal parameter sets for new materials or products, drastically reducing startup waste and time.

Machine Vision-Based Defect Detection: AI can identify defects like gels or holes more accurately and quickly than the human eye, enabling real-time quality control and process feedback.

Conclusion

The evolution path for blown film machines towards 2025 is clear: A modular skeleton supports deeply customized applications; an intelligent nervous system gathers real-time data; and ultimately, AI will inject a soul capable of autonomous learning. Mastering this trend will be key to securing a competitive advantage.

Previous:1500ABC 3 layer co-extrusion film blowing machine Plastic packaging application