Wuxi 850ABA film blowing machine production gloves case

2025-06-30Wuxi customer workshop live shot: 850ABA film blowing machine efficient production of film gloves solution

Against the background of the continuous growth of demand for disposable protective products, a well-known glove manufacturer in Wuxi has achieved a double improvement in film glove production efficiency and product quality by introducing Yuexing Machinery 850ABA film blowing machine many times. This workshop live video directly shows the customer's fourth purchase of a set of equipment. The stable operation and efficient film forming process of the equipment provide a reference for industry customers. Intelligent production example.

Customer pain points and solutions

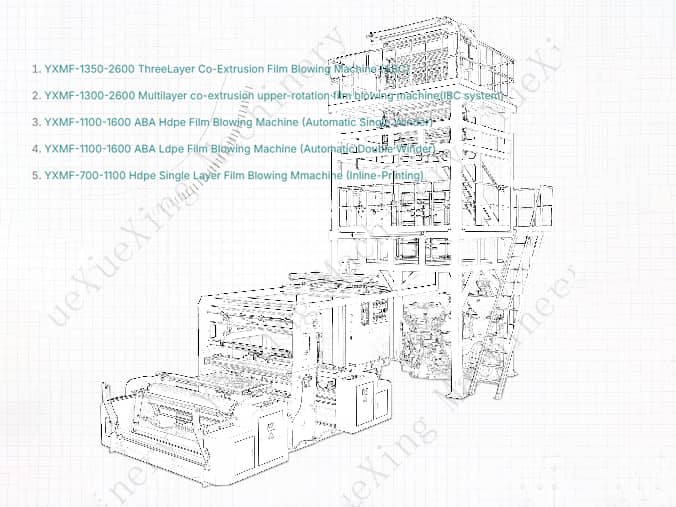

The customer's original production line faces problems such as insufficient production capacity and poor thickness uniformity, which makes it difficult to meet the market's high standard demand for disposable gloves. 850ABA film blowing machine has become the preferred solution with the following advantages:

High-precision die head: ensure that the film thickness error is controlled within ±0.005mm, and the tensile strength of the gloves is significantly improved;

Energy-saving design: energy consumption is reduced by 15% compared with traditional models, and the average daily output is increased by 30%;

Automation control: PLC intelligent system adjusts temperature and air volume in real time to reduce manual intervention.

Highlights of the workshop shot

Raw materials are melted evenly: the screw structure is optimized, no particles are left, and the film bubble is formed stably;

Quickly switch specifications: the same production line can flexibly produce glove films of different colors and thicknesses;

Finished product effect: the film surface is smooth and flawless, and the gloves are flexible after slitting.

Customer feedback

"After the 850ABA film blowing machine was put into production, the product qualification rate increased from 88% to 96%, and the customer complaint rate decreased by 40%. In particular, the delivery cycle of export orders was shortened by 30%." - Customer Production Manager

This case confirms the mature performance of the 850ABA film blowing machine in the field of thin protective products. We look forward to providing customized film blowing solutions to more customers and helping to upgrade production capacity.

For complete videos or technical parameters, please contact our sales team.

Mial:info@yuexingmach.com

Tel:+86 13771616165 Mr.Zhang

web:https://yxfilmblowingmachine.com/

Next:850ABA Film Blowing Machine in Action | Manufacturing Trash/Drawstring/T-shirt Bags