Brazilian customer placed an order for this blown film machine on the spot after personally testing it

2025-11-19The Brazilian customer learned about our product online and, during a visit to China, specifically arranged time to visit our factory for on-site testing. This film blowning machine is the 1800ABC three-layer co-extrusion film blowning machine, primarily used by the customer for Express delivery bag.

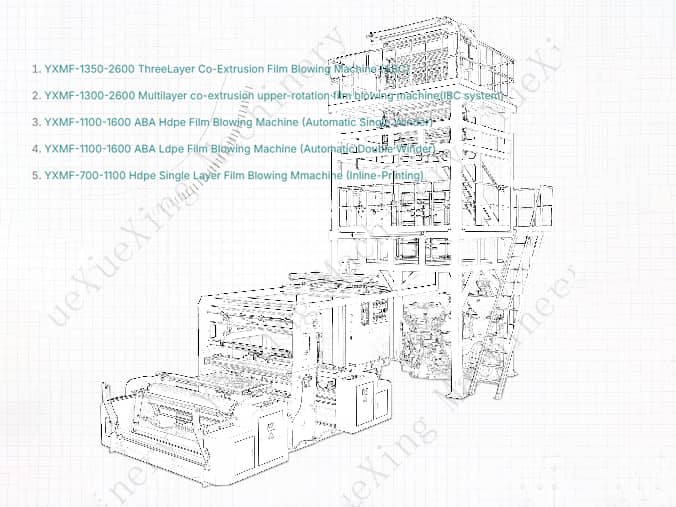

The core of the ABC three-layer film blowning machine consists of three independent extruders, each processing a different plastic raw material. Common raw materials include polyethylene (PE), polypropylene (PP), polyamide (PA), and ethylene-vinyl acetate copolymer (EVA). The raw material can be granular or powdered and fed into the extruder through a hopper.

The biggest advantage of three-layer co-extrusion is its output, a crucial factor in reducing production costs. It offers excellent hardness and wear resistance, capable of plasticizing large quantities of granules even under high speed and high pressure, with a service life of 3-5 years.

The high-speed ABC three-layer blown film machine also provides excellent flexibility and customization options. It can produce a variety of films, such as LDPE, LLDPE and HDPE films, and has multilayer co-extrusion options, which can produce films with reinforcing properties (such as increased strength).

Previous:2600mm Wide-Width Film Blowing Machine Enables Efficient Upgrades for Express Packaging Companies

Next:Nothing...