What is a Film Blowing Machine Used For? A Complete Guide to Its Functions, Principles, and Applications

2025-08-08The content is long, but very comprehensive, please read it patiently!

Introduction: The Role of Film Blowing Machines

A film blowing machine (also known as a film blowing extruder) is a core piece of equipment in the plastic processing industry, primarily used to produce various types of plastic films. From everyday shopping bags and garbage bags to agricultural greenhouse films and industrial packaging films, most plastic films are manufactured using film blowing technology.

Globally, the film blowing process is one of the most efficient and cost-effective methods for plastic film production. According to the Plastics Industry Association (USA), approximately 60% of plastic films worldwide are produced using blow molding technology, widely applied in packaging, agriculture, medical, and other industries.

1. Key Applications of Film Blowing Machines

Plastic films produced by film blowing machines have a wide range of uses, including:

1.1 Packaging Industry

Shopping bags/garbage bags: Made from HDPE (High-Density Polyethylene) or LDPE (Low-Density Polyethylene) for flexibility and strength.

Food packaging films: Such as cling film and vacuum-sealed bags, typically made from LLDPE (Linear Low-Density Polyethylene) or PP (Polypropylene) to ensure food safety.

Industrial packaging films: Including stretch films for securing goods during transportation.

1.2 Agricultural Sector

Mulch films: Improve soil moisture retention and temperature control for better crop growth.

Greenhouse films: Made from EVA (Ethylene-Vinyl Acetate) or PO (Polyolefin) for high light transmission and weather resistance.

1.3 Medical & Specialty Applications

Medical packaging films: Used for IV bags and pharmaceutical packaging, requiring strict hygiene standards.

Barrier films: Used in electronics and high-end food packaging, often produced via multi-layer co-extrusion for enhanced oxygen/ moisture resistance.

2. How Does a Film Blowing Machine Work?

The film blowing process consists of extrusion → inflation → cooling → haul-off → winding:

Extrusion

Plastic pellets (e.g., PE, PP) are melted in an extruder and pushed through a circular die to form a molten tube.Inflation (Bubble Formation)

Compressed air is blown into the tube, expanding it into a film bubble, which is then cooled by an air ring.Haul-Off & Winding

The bubble is stretched by nip rollers to control thickness and width before being wound into rolls.

(A diagram or animation can help visualize the process.)

3. Common Materials Used in Film Blowing

Different plastics determine film properties and applications:

| Material | Properties | Common Uses |

|---|---|---|

| LDPE | Soft, high clarity | Cling film, lightweight bags |

| HDPE | High strength, tear-resistant | Shopping bags, garbage bags |

| LLDPE | Tough, puncture-resistant | Stretch films, heavy-duty packaging |

| PP | Heat-resistant, rigid | Food packaging, medical films |

| EVA | Highly transparent, flexible | Greenhouse films |

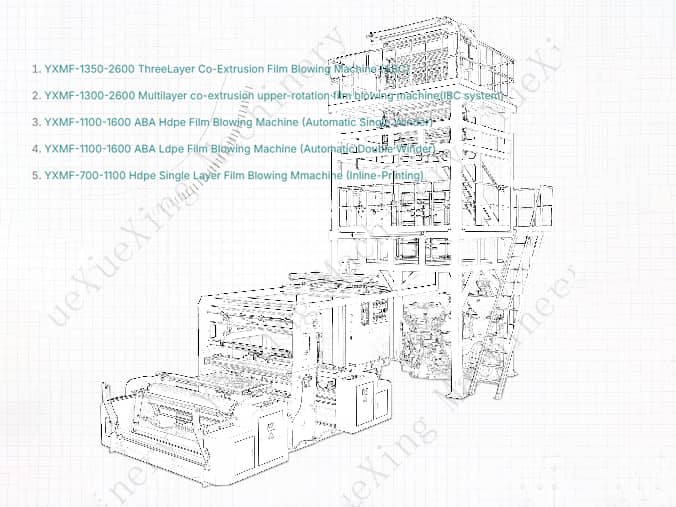

4. Types of Film Blowing Machines

Film blowing machines can be categorized based on structure and functionality:

Single-Layer Blowing Machine

Simple design, suitable for standard films (e.g., HDPE/LDPE).

Double/Multi-Layer Co-Extrusion Blowing Machine

Combines different materials (e.g., PE/PP/EVOH) for enhanced barrier properties.

High-Barrier Blowing Machine

Specialized die design for oxygen/moisture-resistant films (e.g., aluminum composite films).

5. Key Industries Using Film Blowing Machines

Film blowing machines serve multiple industries:

✔ Food Packaging (snack bags, beverage labels)

✔ Agriculture (mulch films, greenhouse covers)

✔ Medical (IV bags, sterile packaging)

✔ Industrial (construction films, electronic protection films)

6. Conclusion: How to Choose the Right Film Blowing Machine?

Based on industry experience, selecting a film blowing machine depends on:

✅ Material compatibility (Does it support multiple plastics?)

✅ Production efficiency (Output rate, energy consumption?)

✅ Automation level (Does it have intelligent control systems?)

As Klaus Stoeckhert, a renowned expert in plastic processing, stated in "Plastics Processing":

"The future of film blowing lies in high precision, energy efficiency, and smart automation."

Our latest 5-layer co-extrusion film blowing machine, equipped with European die technology, produces high-barrier films for premium food packaging, helping clients dominate the market.

Interested in learning more? Contact our engineering team for expert advice!