Factors affecting transparency of film blowing machines and their solutions

2025-05-28The commonly used raw material for film blowing machine is polyolefin, which is a highly crystalline polymer. Therefore, the important factor affecting transparency is the resin raw material. Of course, improving the quality of film blowing machines is also a consideration, but the film blowing machine technology itself has little effect on the transparency of film blowing. Transparency refers to the percentage of the transmitted light intensity with a scattering angle of less than 0.1° to the incident light intensity when the incident light passes through the sample. The higher the transparency of the film, the clearer the image is when viewed from a distance through the film. Transparency is related to the crystallinity and surface flatness of the film. The lower the crystallinity, the more amorphous areas, and the smoother the surface, the higher the transparency is usually.

It can be seen that the best way to improve the transparency of the film is to use lower crystallinity and fine spherulites. This can reduce the surface tension of the film, thereby reducing the thickness of the film. In addition, adding a certain amount of plasticizer to the film can also improve the transparency of the film. Even the most advanced film blowing technology can only improve transparency to a certain extent.

In view of the above, how to solve the problem of film transparency when the raw materials are relatively good? First of all, we should consider that the extrusion temperature of the film blowing machine is too low and the melt is not well plasticized. For this problem, we only need to increase the melt temperature to solve the problem. Another point is that poor cooling after film blowing will also affect the transparency. The corresponding mechanism is to increase the cooling air volume.

Back to the raw materials, the high moisture content of the resin ball will also affect the transparency of the blown film. This problem is relatively simple. You only need to fully dry the resin ball. But if it is glass fiber, special treatment is required, such as applying a layer of transparent protective film on the surface of the resin ball, so as to avoid the resin ball from reducing transparency due to excessive moisture.

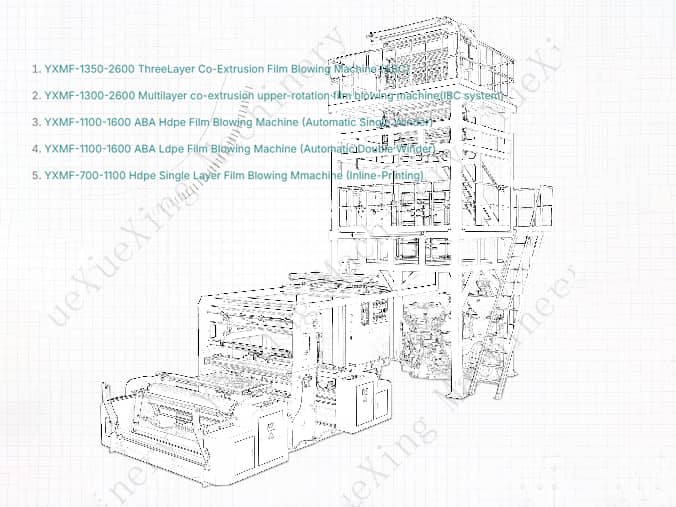

Exceptionally, there are many ways to improve the optical properties of the film, such as adding a small amount of LDPE to linear low-density polyethylene or metallocene polyethylene, adjusting the interlayer density in the three-layer film structure, etc.

In summary, the processing technology that affects the film is nothing more than cooling, raw material polyethylene resin parameters, additives, temperature, and formula design. Specific analysis of different problems can solve the problem.

Previous:2 minutes High-Quality 1800ABA Film Blowing Machines