Temperature control of film blowing machine

2025-05-13In the design and production of film blowing machines, the barrel temperature control design is very important. If the temperature is too high, the plastic in the barrel will decompose and deteriorate; if the temperature is too low, the plastic will not be well plasticized, the fluidity will deteriorate, and the product will not be well formed. Therefore, in the production process, the barrel temperature must be strictly controlled to ensure that the barrel temperature is within the specified range.

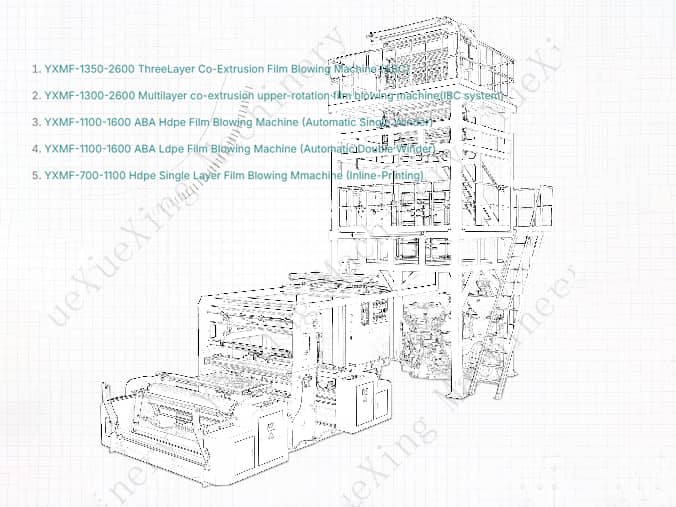

At present, the heating method adopted by film blowing machines is mostly to fasten several sections of heating rings outside the barrel and the die head, and the temperature of each section of the heating ring can be independently controlled. Generally, medium-sized machines are mostly 3-section or 4-section heating. Different machine models have different numbers of heating sections, and the temperature of each section can be adjusted according to process requirements.

Temperature control instrument

In order to control the temperature, the temperature detection problem must be solved first. The commonly used temperature detection element is a thermocouple. In the industrial field, low-end equipment generally chooses temperature control instruments as their temperature controllers. There are many kinds of temperature control instruments. According to the display method, they are generally divided into pointer type and digital LED type; according to the temperature setting method, they are generally divided into knob type, dial type and button type; according to the control method, they are generally divided into two-position type, time proportional type and PID control type. The general principle of selection is to select the corresponding temperature control instrument according to the accuracy requirements of different temperature control, and select the matching temperature sensor and actuator, and make comprehensive considerations based on the cost performance. For the more common film blowing machine equipment on the market, digital LED temperature control instruments with PID control function are generally selected. Such temperature control instruments have relatively high accuracy, and are easy to adjust and maintain.

At present, more and more film blowing machines have adopted PLC technology, which can control the temperature of multiple temperature zones at the same time. It has high control accuracy and strong reliability, and can easily interact with information on the human-machine interface, so as to obtain temperature operation and alarm information.

Previous:1350ABA High Pressure Film Blowing Machine Fully Recycled Materials