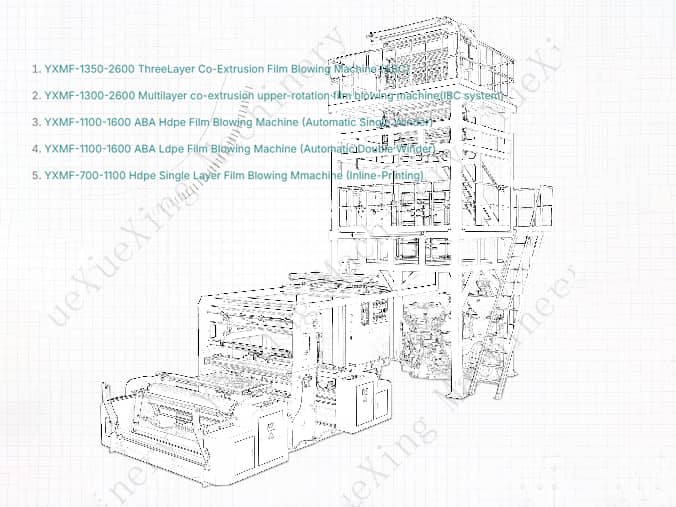

Film Blowing Machine Application Scenarios Classification

2025-12-03Now, let's discuss in detail the first point in customizing a film blowing machine: product positioning. You need to think like a product manager and clarify the first key point—what products do we want to produce? This directly corresponds to the configuration and material selection of the film blowing machine. Products for different application scenarios have vastly different performance characteristics.

1. Daily Consumer Goods Packaging:

Shopping Bags, Flat-top Garbage Bags: The core requirements for these products are cost and basic strength. The film needs good tensile strength and puncture resistance to prevent breakage when lifting heavy objects. Transparency requirements are not high; it can even be semi-transparent or opaque.

High-end Garbage Bags: Emphasize ultimate tensile strength and toughness (tear resistance). Materials such as metallocene polyethylene need to be added, requiring high mixing capabilities from the extruder.

Clothing Bags, Shoe Bags: Require high transparency, high gloss (display effect), and good printability. Strict control is needed for appearance defects such as crystal points and black spots.

2. Industrial and Agricultural Packaging:

Heavy-duty packaging bags (e.g., fertilizer, feed bags): The core requirements are high strength, high rigidity, and UV resistance. These are typically thick, requiring high-powered extruders to ensure plasticization, and may require the addition of UV-resistant masterbatches.

Mulch film, agricultural greenhouse film: Requires weather resistance (anti-aging), heat insulation, and anti-drip/anti-fogging properties. May require multi-layer co-extrusion and the addition of functional masterbatches.

3. High-end Functional Packaging:

Food packaging (e.g., bread bags, freezer bags, cooked food bags): The core requirements are hygiene and safety, heat sealability, and barrier properties. May require oxygen barrier properties (e.g., EVOH layer) and moisture barrier properties, requiring equipment and material contact parts to be made of special stainless steel and easy to clean.

Fresh food preservation film, modified atmosphere packaging: Has precise requirements for gas permeability (oxygen, carbon dioxide). This almost always involves multi-layer co-extrusion (e.g., PA/EVOH barrier layer), posing a significant challenge to the precision control of interlayer thickness in the equipment.

Pharmaceutical and electronic product packaging: Requires extremely high cleanliness, dust-free conditions, low static electricity, and excellent mechanical protection. Special requirements exist for the production environment, equipment sealing, and material cleanliness.

Previous:How to Precisely Customize Your Blown Film Machine? A Comprehensive Buying Guide

Next:Nothing...